Geotextile membrane – a type of manmade fabric – is often utilized in construction and landscaping projects. Available in varying sizes and weights, it can be leveraged to separate, filter, reinforce, protect, or drain materials, while its utilization also serves to enhance soil stability and manage erosion.

A wide range of geotextile membranes exist, namely, woven and non-woven. Woven fabrics are formed using polypropylene or polyester yarns, artfully interwoven to build the classic textile configuration. Alternatively, non-woven membranes are made from polypropylene or polyester fibers which are stitched together manually using needles or fused using heat in order to form the desired fabric.

Before selecting the appropriate geotextile membrane for your landscape or construction venture, climate conditions, the characteristics of the soil, the amount of foot or vehicle traffic expected, and the term of service must all be taken into account.

When searching for the ideal geotextile for a project set in an area of elevated heat, Polypropylene is the most reliable material – resilient enough to cope with hot circumstances without compromising its strength.

In cold climates, it is of the utmost importance to ensure a geotextile membrane can be used effectively without any degradation due to adverse temperatures. Polypropylene is proven to be the most suitable choice for such climate conditions.

While selecting the optimal geotextile membrane for any given project, the nature of soil, including sandy soil, should be taken into consideration. Polypropylene fabric is the recommended material when dealing with sandy terrain, since it is highly resistant to tearing and puncturing.

For projects situated in a clay-induced environment, selecting a geotextile membrane that can maintain structural solidity is paramount. Polypropylene is advised for its ability to defy stretching and ripping in such soil conditions.

For projects situated in heavily trafficked areas, it is wise to opt for a geotextile membrane that can bear up to abrasions and deterioration. Among various options, polypropylene is the ideal selection for such demanding conditions.

In locations that are not especially traffic-heavy, selecting a geotextile membrane with both puncture and tear resistance should be a priority. As for what’s best suited for these conditions, polypropylene is the way to go.

Duration

When it comes to feats requiring a short-term solution, selecting a geotextile membrane which is capable of easy removal is essential. Among the options, polypropylene stands out as the most advantageous for these types of applications.

For any permanent projects, selecting a geotextile membrane that won’t deteriorate over the course of time is of critical importance – in this situation, polyester is the wisest option.

Related Product

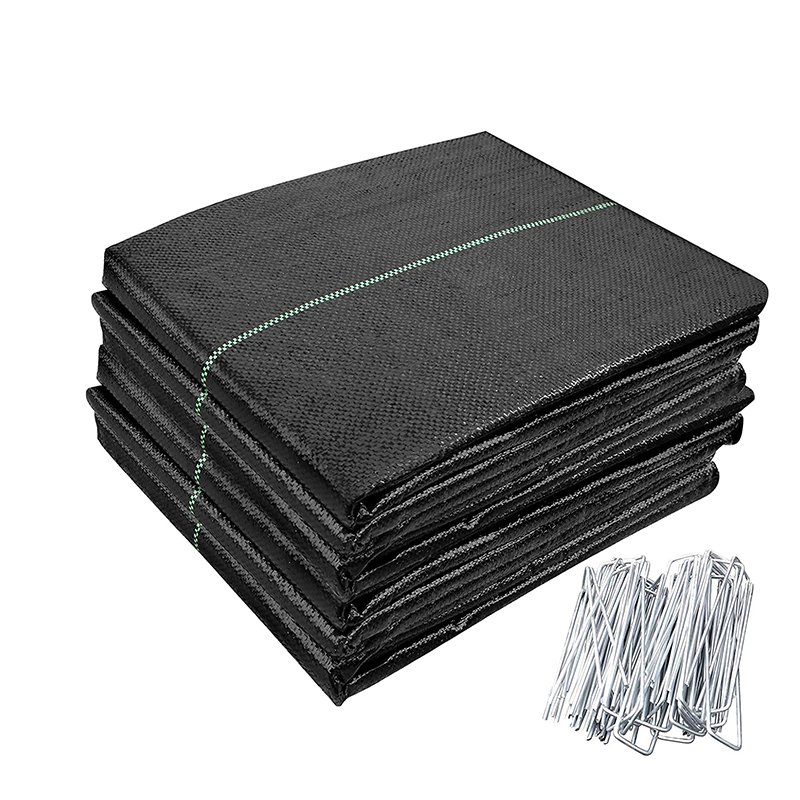

Woven Geotextile/Weed Mat

PP Woven Geotextiles are a series geotextiles made of high-performance polypropylene woven geotextile fabrics combining strength, durability and robust design. All these PP woven g […]

Wire Backed Silt Fence

The Wire Back Silt Fence is a strong erosion control fence designed for areas with demanding silt and erosion control requirements. Offering more strength and stability than a stan […]

Heavy Duty Landscape Fabric

High Strength &Durability: 5.8oz heavy duty landscape weed barrier fabric, made of tightly woven polypropylene fabric needle which punched with UV-stabilized. 98.7% opaque to l […]

Silt Fence

Product Weed Mat / Ground cover/Slit fence Weight 70g/m2-300g/m2 Width 0.4m-6m. Lengths 50m,100m,200m or as your request. Color Black,Green,White ,Yellow or As your request […]

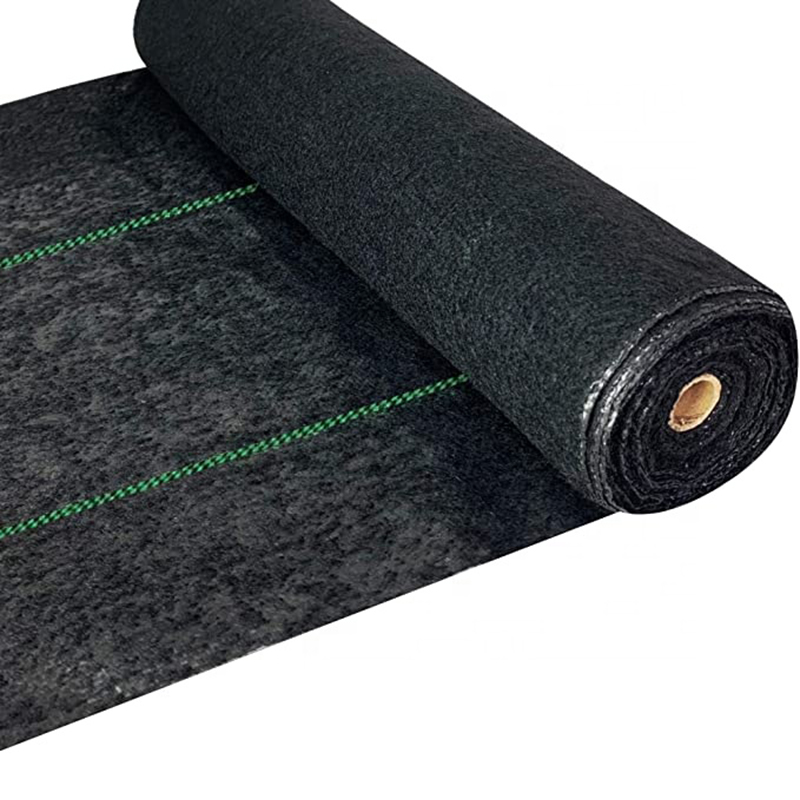

Non-Woven Geotextile

Geotextiles are permeable geosynthetic materials made by needling or weaving synthetic fibers. Geotextile is one of the new geosynthetic materials, and the finished product is clot […]

Bluekin Weedmat: Your Secret Weapon for a Low-Maintenance and Beautiful Garden

Are you tired of spending countless hours weeding and maintaining your garden? Look no further than Bluekin Weedmat, the ultimate solution for a low-maintenance and beautiful garde […]

Hdpe Geomembrane

Product Features: They have strong ability for waterproof,anti seepage and isolation, aging resistance, good welding performance, convenient construction, root resistance and other […]

Post time: 2023-06-23